Why use a VE Dual Expanding Plug Valve

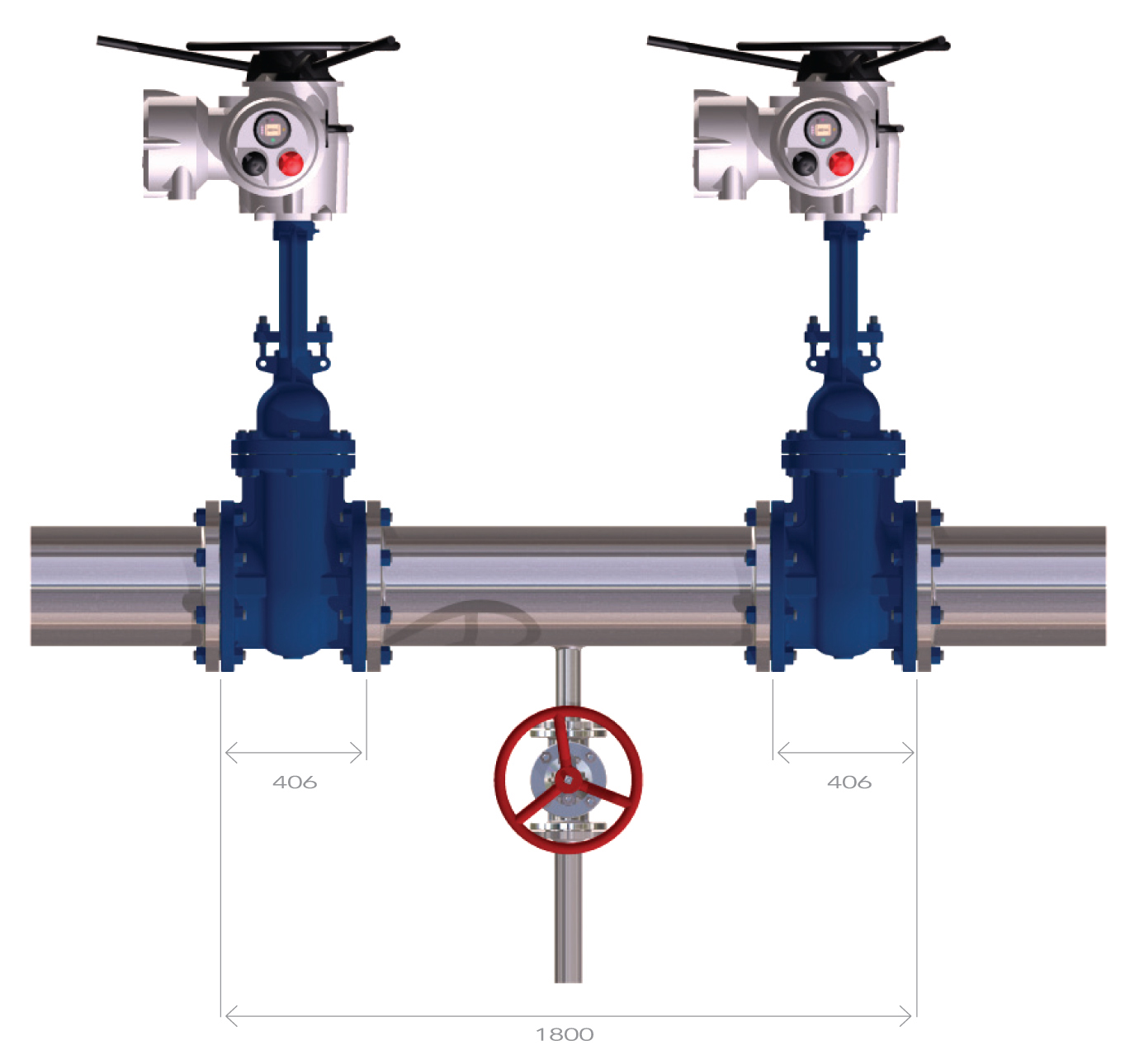

Gate Valves

- No thermal pressure relief, only bleed function

- Seat wearing increase – frequent maintenance intervals

- Large installation space required

- Two actuators, two input/output signal needed to operate the valves

- Two valves, more joints, higher maintenance costs

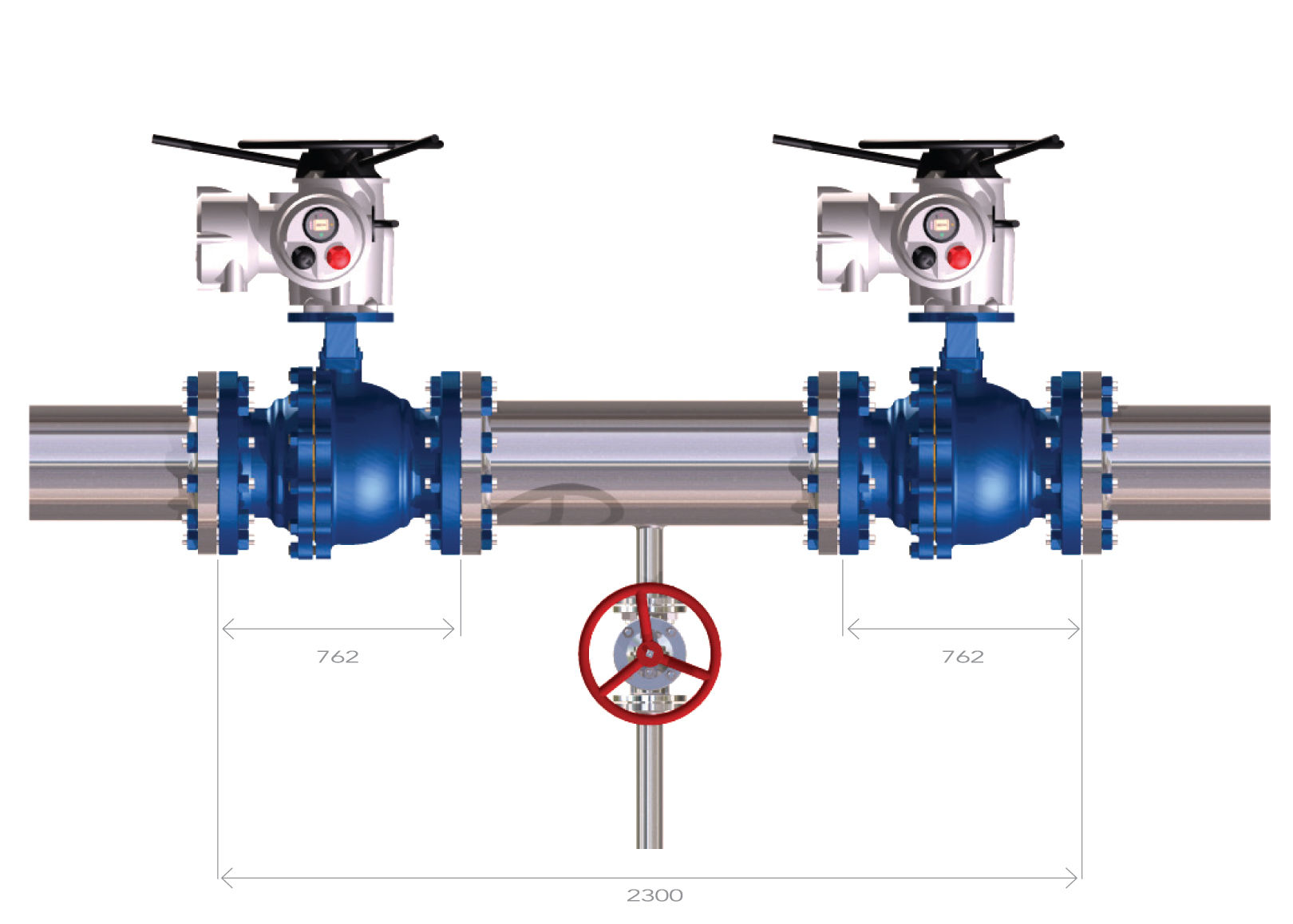

Ball Valves

- No thermal pressure relief, only bleed function

- Seat deterioration due to abrasion increase maintenance intervals

- Large installation space required

- Two actuators, two input/output signal needed to operate the valves

- High operating torque requires larger actuation

- Expensive valve execution

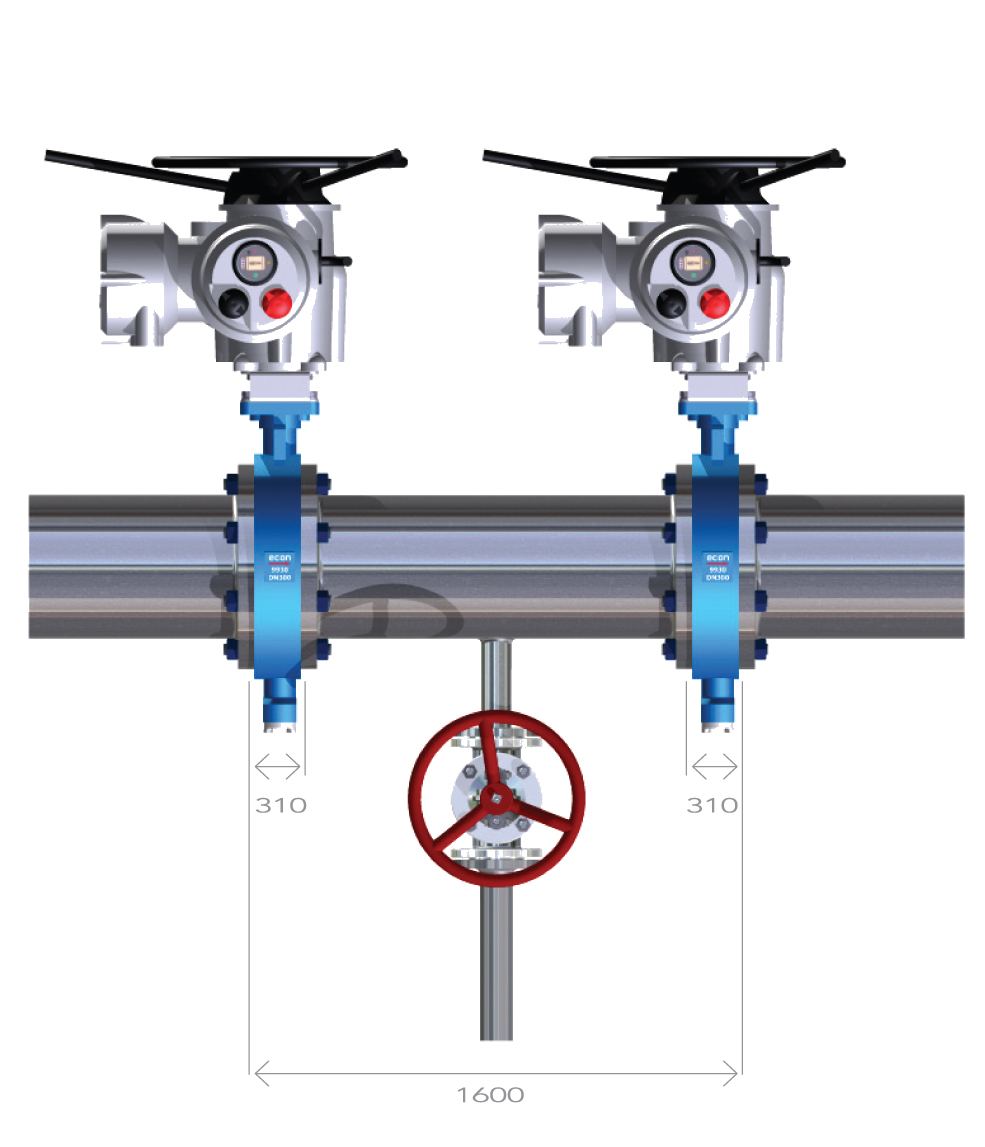

Butterfly Valves

- No thermal pressure relief, only bleed function

- Not piggable

- Large installation space required

- Two actuators, two input/output signal needed to operate the valves

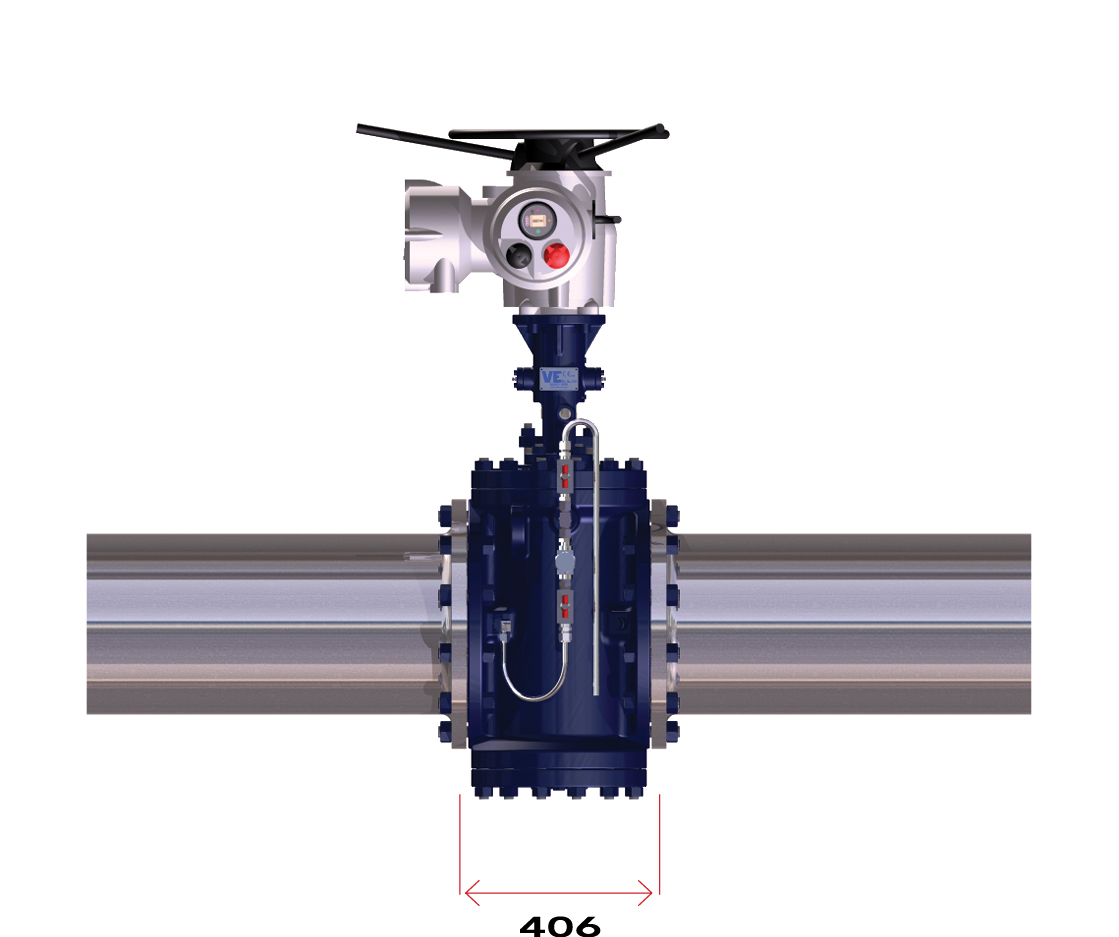

Double Block and Bleed Solutions

- Permanent integral thermal relief and bleed function

- In-line maintenance in case of seal replacement

- Very short installation space required

- Double Isolation function, according to API-6D/ISO14313

- Only a single actuator required to operate the valve

For many years different valves and valve combinations have been used as a solution for blocking and bleeding, sampling or draining lines. Traditional valves (gate) or valve combinations can degrade over time and result in loss of product and frequent maintenance. Unlike other valve types, the VE® Dual Expanding plug valve creates an optimum seal without causing any abrasion and wear. Providing a “zero-leakage” solution, upstream and downstream, securing a long life-time of the seals and valve, as well as a low opening- and closing torque. This unique design is combined with a bleed function, all in one valve, saving space as well as providing a reliable, safe and economical solution.